- Introduce

- Advantage

- Parameter

- PDF Download

PDF

PDF

LD1857 small automatic forming frying machine includes a heating mechanism composed of a controller, an electric heater, an oil groove, and a forming mechanism consisting of an electric motor, a bracket, a storage device, and a forming tool. It is designed according to the same fried characteristics of the materials in the fried. The operation of deep-fried food billet making and deep-fried technology moving, turning, discharging, and oil draining is completed automatically and continuously with the same small equipment under the control of the single-chip microcomputer.

The advantages of the frying machine:

The advantages of the frying machine:

1.Small volume, lightweight, easy installation, conducive to the popularization.

2.Block structure, easy to clean.

3. Continuous automatic production, the output can be set or adjusted at any time.

4. Single machine output is large, energy and labor consumption is low.

5. Suitable for a variety of raw materials, product design, and color varieties change quickly.

LD1857 small automatic forming frying machine configuration:

LD1857 small automatic forming frying machine configuration:

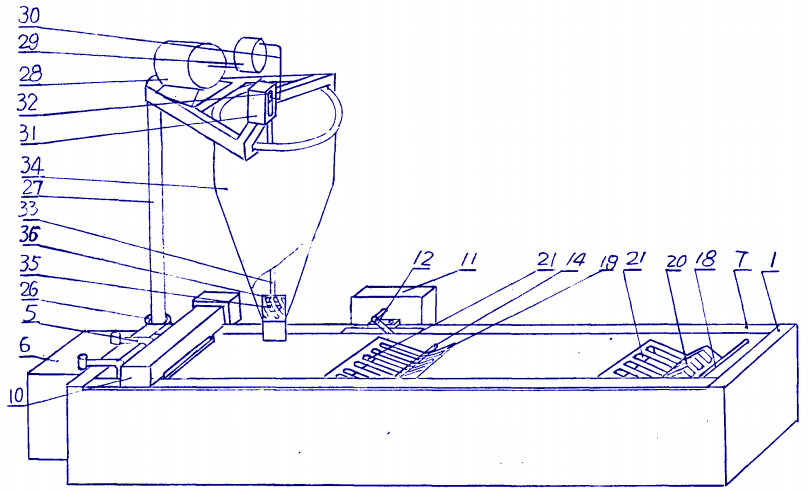

Figure 1

Figure 1

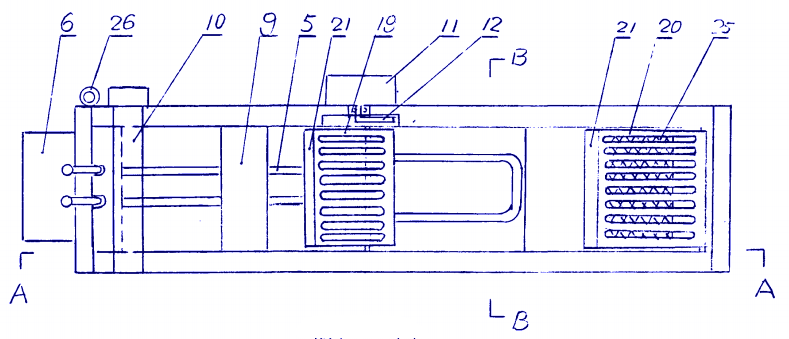

Figure 2 top view of oil groove and support

Figure 2 top view of oil groove and support

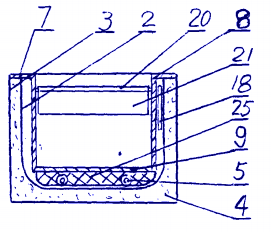

Figure 3 A-A view

Figure 3 A-A view

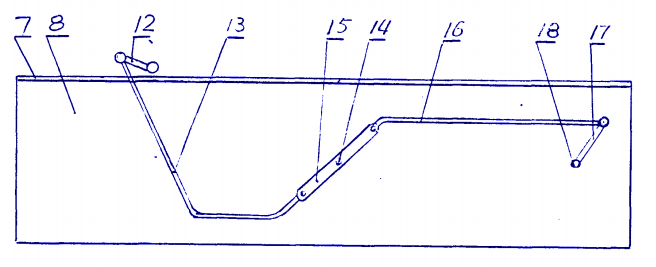

Figure 4 B-B view

Figure 4 B-B view

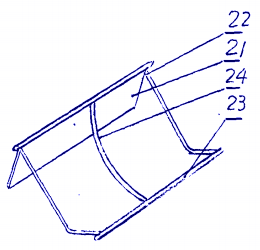

Figure 5 schematic diagram of baffle plate

Figure 5 schematic diagram of baffle plate

Oil tank 1, inner shell 2, shell 3, insulation material 4, electric heating tube 5, electronic heater controller 6, support 7, vertical side panel 8, oil flow control panel 9, hot gas jet device 10, controller 11, short connecting rod 12, long connecting rod 13, turning plate rotating shaft 14, little connecting rod 15, long connecting rod 16, small connecting rod 17, rotating shaft 18, bending plate 19, discharging turning plate 20, baffle 21, the support rod 22, baffle shaft 23, spring sheet 24, grooved stainless steel net 25, short tube 26, stand 27, motor 28, eccentric wheel 29, connecting rod 30, slide valve 31, slide valve 32, stamping parts 33, storage 34, punch 35, forming mold 36

Equipment performance:

Equipment performance:

1. Stainless steel materials

2. Control fuel temperature

3. Automatic slag removal, and can be equipped with a circulating filtration system

4. Easy cleaning, automatic oil filling

5. The heating mode can choose electricity, liquefied gas or natural gas, leakage protection

Equipment technical parameters:

Equipment technical parameters:

| Dimensions | 4000X1800X2680mm | 6000X1800X2680mm | 8000X1800X2680mm |

| Effective size | 2180X800X100mm | 4180X800X100mm | 6180X800X100mm |

| Oil capacity | 600L | 1000L | 1500L |

| Machine weight | 1200KG | 1800KG | 2600KG |

| Electric power | 2.4KW | 2.4KW | 2.4KW |

| Thermal power | 200KW | 300KW | 400KW |

| Rated voltage | 380V | 380V | 380V |

| Frequency | 50HZ | 50HZ | 50HZ |

| Output value | 200-400KG | 400-600KG | 600-800KG |

| Temperature range | Room temperature—230℃ | Room temperature—230℃ | Room temperature—230℃ |

Characteristics of LD1857 small automatic forming frying machine:

Characteristics of LD1857 small automatic forming frying machine:

1. The feeding end of the heating mechanism is provided with a hot air jet device composed of a fan, an electric heater, and a controller.

2. The lower end of the two sides of the control mechanism support is connected by the horizontal oil flow control panel, which is distributed intermittently above the heating tube.

3. The oil groove is an open groove, which may be either straight or u-shaped or annular.

4. Groove stainless steel filter is arranged under the discharge port of the oil groove.

LD1857 small automatic forming frying machine PDF

LD1857 small automatic forming frying machine PDF

The advantages of the

The advantages of the