- Introduce

- Model

- Service

- PDF Download

PDF

PDF

Cornflakes are a new type of fast food. They can be stored for a long time and are easy to carry. They can be eaten directly and processed into other foods. Mix it with cold milk and yogurt for breakfast. Automatic cornflakes are the same machines that make cornflakes. In today’s fast-paced life, when it comes to eating and drinking, we also prefer the fast and straightforward cornflakes breakfast cereal.

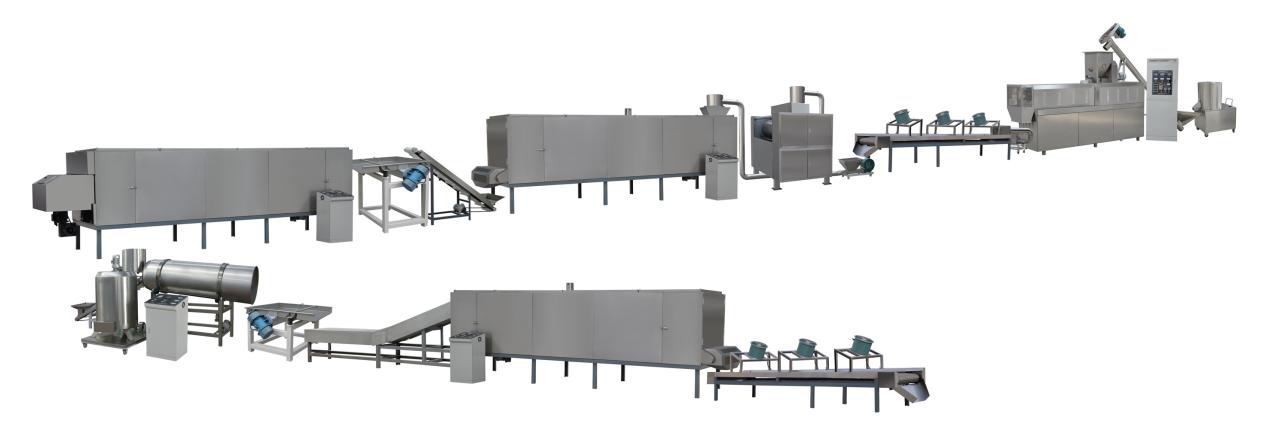

As one of the professional grain and food machinery manufacturing suppliers, our automatic food production line has a variety of models. Each type has a different output, and you can choose the right machine for your needs. The right machine can save your investment cost and bring you more profit space.

Corn flakes produced through a corn production line

Cornflakes workmanship:

Cornflakes workmanship:

Baked nachos: grits – pressure cooking – drying – conditioning – rolling – baking – seasoning – baking nachos.

Tortilla chips: grits – soaked in acid – neutralized – washed – drained – grated – set – baked – sifted – Fried – flavored – Fried tortilla chips.

Cornflake production line

Model and product specification:

Model and product specification:

| name \ type | DL56-III | DL65-II | DL70-II | DL85-II |

|---|---|---|---|---|

| Full name | Twin-screw extruder | |||

| Line kinds | Three lines four phase(2 fire line 1null line 1baseline) | |||

| operation | Press the knob manually | Press the knob manually | Press the knob manually | Press the knob manually |

| Mains input | 380V/50HZ(Other supply voltage can be customized) | |||

| Installation power | 35KW | 46KW | 46KW | 90KW |

| Power consumption | 25KW | 30KW | 30KW | 55KW |

| Production capacity | 120-150Kg/h | 150-180Kg/h | 200-260Kg/h | 300-500Kg/h |

| Size dimension | 2.5×0.8×1.8m | 3.2×1.0×2m | 3.2×1.0×2m | 4.5×1.2×2.4m |

| Stainless steel thickness | 1.2mm | |||

| The screw material | 38CrMoAL/38Luo manganese aluminum | |||

| The length of the screw | 1050mm | 1520mm | 1520mm | 1563mm |

| The screw diameter | 65mm | 65mm | 70mm | 85mm |

| Motor power | 22kw | 30kw | 30kw | 55kw |

| Heating power | 2*5kw 10kw | 10kw | 12kw | 16kw |

| Feeding power | 0.75KW | 0.75KW | 0.75KW | 1.5kw |

| Rotary cutting power | 0.75KW | 0.75KW | 0.75KW | 1.5kw |

| Oil pump power | 0.37kw | |||

| Water circulation | customize | |||

| This machine is composed of a feeding system, extrusion system, rotary cutting system, heating system, driving system, and control system. The equipment adopts advanced screw extruding technology, using high temperature and high pressure, the material is matured and puffed into shape, which is completed at one time. The main machine adopts frequency conversion speed regulation to ensure the stability of the production process. Products have a variety of colors, numerous in variety, beautiful appearance, natural, lifelike, exquisite texture, wide use of raw materials. | ||||

Your breakfast cereal cornflakes business plan the preparatory work as follows:

If you have plans to start a cornflakes business, you should do some preparation. Adequate preparation can make your business run more smoothly.

First, you should know the cost of the investment, the cost of the corn chip line, the floor space, and the productivity of the machine. By understanding these conditions, you can choose a suitable machine. Different investors have different amounts invested.

Second, choose a reliable manufacturer. There are many puffed food machine manufacturers on the market. You should compare factory size, professional technical personnel, technology, pre-sale service, and after-sales service, food machinery quality, etc. Comprehensive comparisons can help you make good choices.

Due to our favorable reputation, many customers are looking for corn flakes production line machines from our leader microwave equipment company. We have a professional research and development team, production team, sales team, trade documentation team, and after-sales service team. Therefore, we can provide a one-stop service for you. You can rest assured purchase food extruding machine or corn chip making machine from our factory.

Third, prepare the raw materials for processing corn flakes. If you don’t have raw materials, you should find a partner who supplies the grain. High-quality ingredients can be used to make high-quality corn flakes.

When you want to buy a nachos machine, you should make these preparations. You have to prepare everything carefully before you invest and then do twice as much with half as much effort.

Good service of Leader manufacturing machine:

1. We will provide more detailed information about your question by email and telephone when we first receive your inquiry. We will arrange an expert to help you install the cornflakes machine. If you need it, our engineers will train your workers.

2. If you encounter any problems during operation, please contact us to help you solve them.

3. Our Leader is one of the professional suppliers of automatic cornflakes. We can provide lifelong maintenance service for the machines you purchase at any time.

The leader microwave equipment company is one of the reliable manufacturers of food machines. Has been exported to Algeria, Egypt, Russia, Ukraine, Australia, Argentina, Brazil, Saudi Arabia, Libya, Syria, and other countries.Looking forward to cooperating with you to purchase our food processing equipment immediately!

Automatic cornflakes production line PDF

Automatic cornflakes production line PDF

Cornflakes workmanship:

Cornflakes workmanship: