- Introduce

- Model

- Advantage

- PDF Download

PDF

PDF

Animal biscuit making equipment, as we know it literally, is a mechanical device for making biscuits shaped like animals. The primary raw material for making biscuits is wheat flour, sugar, oil, eggs, milk, and other auxiliary materials. According to the formula and mechanical production process, cookies can be divided into tough cookies and crisp cookies.

- Animal biscuit

- Animal biscuit

In addition to animal biscuit making equipment, we have many types of puffed food machines for sale. It’s used to squeeze potatoes, beans, and cereals into a casual snack. Of course, if you want to make cookies in other shapes, you just need to change the mold. Therefore, choose our Leader machine; you can produce biscuits, cookies, puffed snacks, and so on. Invest in devices that require only a small amount of money, and you can make a large profit from them. Choose the right machine immediately!

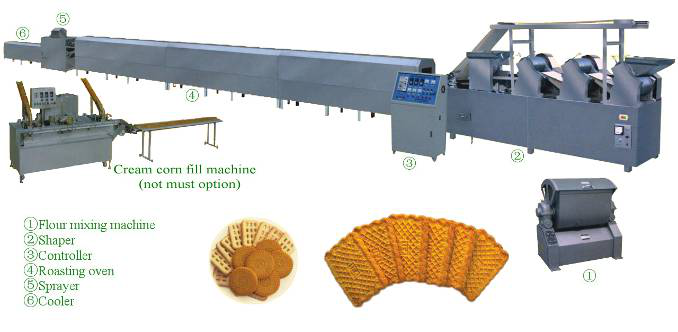

The biscuit production line includes 1 dough mixer, 1 molding head, 1 oven, 1 cooling line distribution box, and 2 molds.

After two months of E-mail communication, we received a man from Sudan in the factory. He is one of the largest traders in Sudan. This visit is mainly to see the biscuit production line/biscuit production machinery/biscuit machine. Biscuits are very popular in Sudan, and our biscuit machine is very popular in the market.

- Entertaining customer

- Entertaining customer

The client’s schedule is very tight, and he can only stay here for 4 hours. To make this trip worthwhile, we have carefully arranged visiting activities for the client. Reception — show the machine working — talk to the engineer — talk to the boss. Through a series of exchanges, the customer was pleased about the visit and decided to buy our machinery.

Model and product specification:

Model and product specification:

| Biscuit production line production equipment | |||

| Host Model | LD225 | LD400 | LD600 |

| Power and voltage | 380V/50HZ | 380V/50HZ | 380V/50HZ |

| Installed Capacity | 28.5KW | 110KW | 220kw(gas type25kw) |

| Impression roller | Φ205×205mm | 85kw | 160kw(gasconsumption25-30kg/h) |

| Baking temperature | 200-300℃ | 200-300℃ | 200-300℃ |

| Production capacity | 50~60Kg/h | 150-200Kg/h | 300-500kg/h |

| Production line length | 21000mm | 43000cm | 60000mm |

A customer in Iran contacted our company by introducing a local friend and visited our company to inspect the pet food production line.

Pet food production line endows pet food with novel shape, unique taste and color, and the most scientific nutrition ratio. It is easy to digest and other characteristics to adapt to the growing pet food market, colorful shape, and taste to meet the requirements of all kinds of pets. The Pet food production line consists of a powder mixer, twin screw extruding machine, air feeder, dryer, and seasoning line.

What are the advantages of animal biscuit making equipment?

What are the advantages of animal biscuit making equipment?

1. A wide selection of raw materials. Flour, cornflour, wheat flour, rice flour, and a variety of grain powder mixture can add cocoa powder, milk powder, egg yolk powder, fruit and vegetable powder, nut powder, and so on to make a variety of flavors of biscuits.

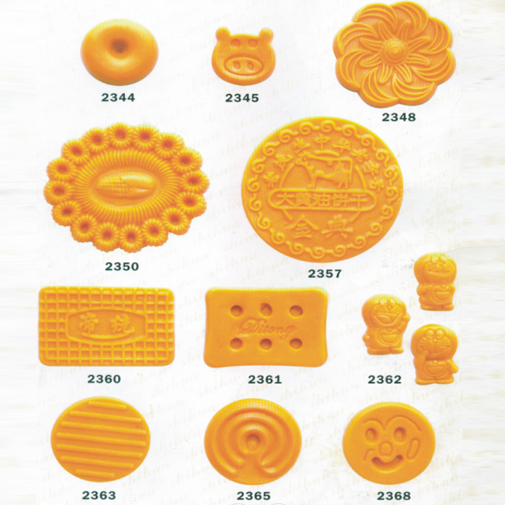

2. A wide range of biscuits can be made. By changing molds and raw materials, middle and high-end biscuits can be produced that popular in the market.

3. Simple operation, easy to use. Our leader microwave equipment company’s biscuit production line needs only one technical worker,2-3 ordinary workers can complete the operation of the whole line and carry out normal production.

4. Cookie making process:

Dough blending – roll molding – baking – spray – cooling – packaging

- customer trial production of biscuits

- part type of biscuit

Provide perfect service to customers:

Provide perfect service to customers:

1. We will provide more detailed information about your concerns by email and telephone when we first receive your inquiry.

2. We will arrange experts to help you install the biscuit production line machine, if you need, our engineers will train your workers

3. If you encounter any problems during operation, please contact us to help you solve them.

4. Our Leader Machinery provides lifelong maintenance for you.

We offer a 12 – month warranty, lifetime maintenance. During this period, our company provides free maintenance service due to the fault of the machine itself. Our company also actively provides maintenance plans and suggestions for problems that occur after the warranty period of more than one year. If necessary, we can send engineers to the customer’s factory for maintenance.

Animal biscuit making equipment PDF

Animal biscuit making equipment PDF

Model and product specification:

Model and product specification: