- Introduce

- Advantage

- Feature

- PDF Download

PDF

PDF

LD1858 continuous frying machine includes a frying pool, the bottom of which is fixed with a heating pipe; The frying pond consists of the inlet end and the outlet end. The inlet end is equipped with a driving plate and a driving motor. The outlet end is also equipped with an output net belt motor.

At present, most enterprises still use a small workshop for processing when frying various foods. But the little workshop processing is the use of simple small equipment, only a low volume of production, not only high labor intensity but also the processing speed is very slow, seriously affecting the work efficiency and bringing a lot of losses to the processor.

Advantages of the frying machine:

Advantages of the frying machine:

With continuous operation, the oil can be filtered without manual, which increases the cleanliness of the oil and simplifies the frying process. Increased processing speed, reduced staff production intensity, can improve the quality of fried food and can achieve large-scale fried production.

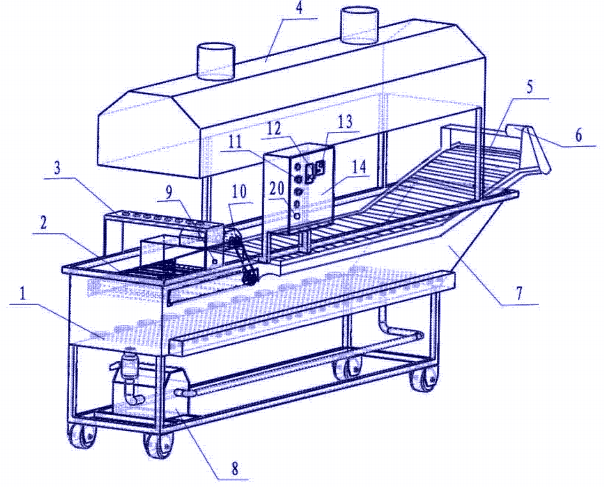

Schematic diagram of LD1858 continuous frying machine:

Schematic diagram of LD1858 continuous frying machine:

Figure 1

Figure 1

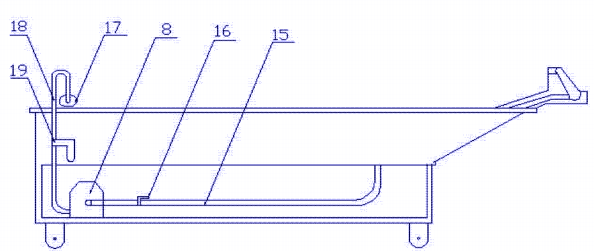

Figure 2 schematic diagram of oil filter circulation device

Figure 2 schematic diagram of oil filter circulation device

1.Heating tube, 2. Drive plate, 3. Spray rack, 4. Extraction hood, 5. Output mesh belt, 6. Output mesh belt motor, 7. Deep-fried pool, 8. Oil pump, 9. Drive plate stops control device, 10. Drive motor, 11. Main power switch, 12. Output network belt switch, 13. temperature meter, 14. control box, 15. oil inlet pipeline, 16. oil inlet control valve, 17. oil filter net, 18. oil return pipeline, 19. oil return control valve, 20. standby heating tube switch

Equipment performance:

Equipment performance:

1.Stainless steel materials

2.Automatic temperature control

3.Fried timing

4.Automatic mixing

5.Automatic discharging

6.The heating method can choose electricity, liquefied gas or natural gas

The working process of LD1858 continuous frying machine:

The working process of LD1858 continuous frying machine:

When the protruding part on the drive plate encounters the control stop device of the drive plate 9, the drive plate 2 stops operation, and the time relay of the drive plate begins to work. At this time, the raw materials to be fried are put on the drive plate 2. When the time relay of the transmission plate reaches the time limit, the transmission plate 2 will run. When the second plate of the transmission plate runs into the control stop device of the transmission plate 9, the transmission plate will stop running, and then the pulp spraying rack 3 will start. When the drenching rack time relay reaches the time, the drive plate converter begins to work, and the drive plate 2 continues to operate. When the drive plate runs to the place where it meets the output mesh belt 5, it turns over and turns the raw material to the output mesh belt 5. At this point, the raw material starts to fry in the frying pond, and then fried, the finished product is transported to the outlet through the output mesh belt.

The features of the frying machine:

The features of the frying machine:

1. The drive plate converter is used to control the speed of the drive plate.

2. The drive plate time relay is used to manage the time the drive plate stays.

3. A temperature meter is installed on the outer surface of the control box to display the frying tank’s temperature.

4. The heating tube includes the typical heating tube and the standby heating tube. The outer surface of the control box is also equipped with the stand by heating tube switch. The default working state is the heating tube in use. When the typical heating tube is damaged, turn on the standby heating tube switch. The standby heating tube can continue to be heated.

5. The bottom of the frying pond is a sloping bottom, and the bottom of the frying stank is lower at the exit than the bottom of the frying stank is at the entrance.

LD1858 continuous frying machine PDF

LD1858 continuous frying machine PDF

Advantages of the

Advantages of the