- Introduce

- Advantage

- Parameter

- PDF Download

PDF

PDF

LD1859 automatic bagel deep-fried machine including body, oil pool, the material network belt, and the material slide setting at both ends of the fuselage, automated control system.

Existing fried machinery is mainly the drum type fried machine and the net belt type fried machine. The drum type deep fried machine is mostly suitable for the fried nuts, and the net belt type deep fried machine is mainly suitable for the fried leisure, puffing food. Neither the drum frying machine nor the net belt frying machine is ideal for the fried doughnut food. Because the billet before the donut frying has to be shaped to leaven, the appearance is soft and sticky, easy to adhere, and the lightweight of the dough will float on the oil surface during the frying process.

Advantages of LD1859 automatic doughnut frying machine:

Advantages of LD1859 automatic doughnut frying machine:

As the net belt is eliminated, it can prevent the bagel billet adhesion and maintain its beautiful appearance. The automatic bagel deep-fried machine’s automated control system can also adjust the temperature of the oil press and the time of bagel deep-fried according to the needs, thus improving the work efficiency. The machine can realize automatic feeding and discharging, no manual operation, save time and labor cost, so that the economic benefit is much improved, so it has good promotion value.

Configuration of the frying machine:

Configuration of the frying machine:

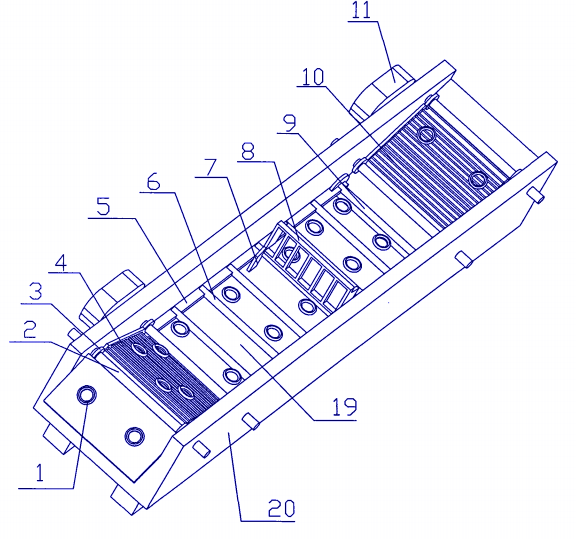

Figure 1 schematic diagram of main frying machine

Figure 1 schematic diagram of main frying machine

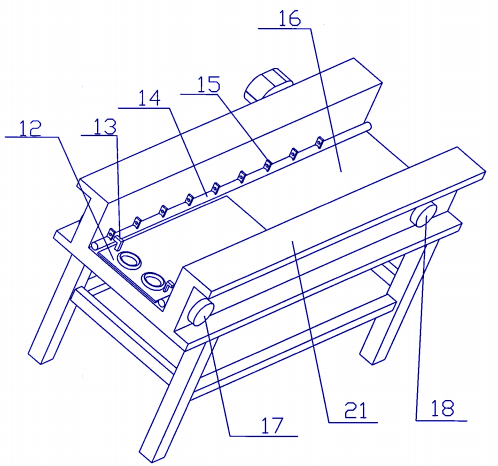

Figure 2 schematic diagram of conveyor

Figure 2 schematic diagram of conveyor

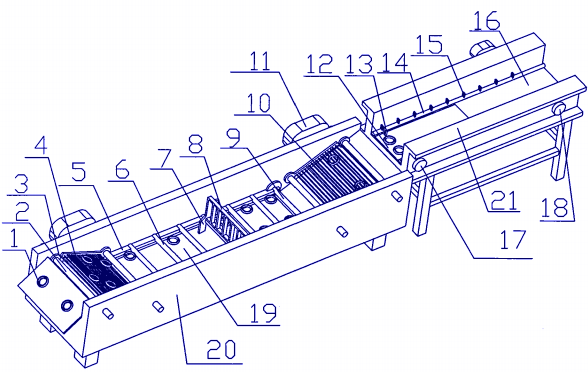

Figure 3

Figure 3

1. Donut; 2. Driveshaft; 3. Sprocket; 4 discharging slide; 5. Ring chain; 6. Connecting rod; 7. CAM mechanism; 8. Flip plate; 9. Driven shaft; 10. Feeding net belt; 11. Motor; 12, cloth; 13. Tie rod; 14. Ring chain; 15. Vertical board attachments; 16. Tablet; 17. Driven shaft; 18. Driveshaft; 19. Oil tank; 20. Main frying machine; 21. Conveyor

Equipment performance:

Equipment performance:

1. Stainless steel material

2. Automatic temperature control

3. Fried timing

4. Automatic mixing

5. Automatic discharging

6. The heating method can choose electricity, liquefied gas or natural gas

Equipment technical parameters:

Equipment technical parameters:

Dimensions :3000X810X1130mm

Tank size :2300X500mm

Oil capacity :150L

Rated voltage :380V

Frequency :50HZ

Yield :2000piece/h

Temperature range:≤260℃

The working process of LD1859 automatic donut frying machine:

The working process of LD1859 automatic donut frying machine:

When working, the bagel is formed and placed on the conveyor plate after leavening. The plate is covered with the cloth of a certain length. A pull rod is fixed at the front end of the fabric, a tie rod is arranged in front of the upright plate attachment, set on the ring chain. When the circular chain circulates forward, the vertical plate attachment drives the tie rod, cloth, and the bagel on the fabric to move forward, and sends the bagel to the net feeding belt of the main frying machine to enter the oil pool. The circular chain of the main frying machine circulates to drive the bagel forward. As the bagel floats on the oil surface, when the connecting rod moves forward, it pushes the bagel forward. When the bagel moves to the middle part of the oil pool, the connecting rod pushes the CAM mechanism to make the roll plate rotate and turn the bagel 180 degrees. The link then pushes the bagel forward, sending it to the upward-sloping outlet, sliding it to the moving outlet, and repeating this cycle.

LD1859 automatic donut frying machine PDF

LD1859 automatic donut frying machine PDF

Advantages of LD1859 automatic doughnut frying machine:

Advantages of LD1859 automatic doughnut frying machine: