In recent years, more and more people keep pets, and the demand for pet-related products is also increasing. Pet toys and pet food are in short supply in many manufacturers, and the demand for pet food extruders is also increasing.

We are a professional manufacturer of pet food extruders with a wide range of equipment, including sandwich rice snack machines, fish feed extruder, food puffing snack machines, and so on. These are our hot selling equipment, exported to many countries and regions, bringing great convenience to local customers.

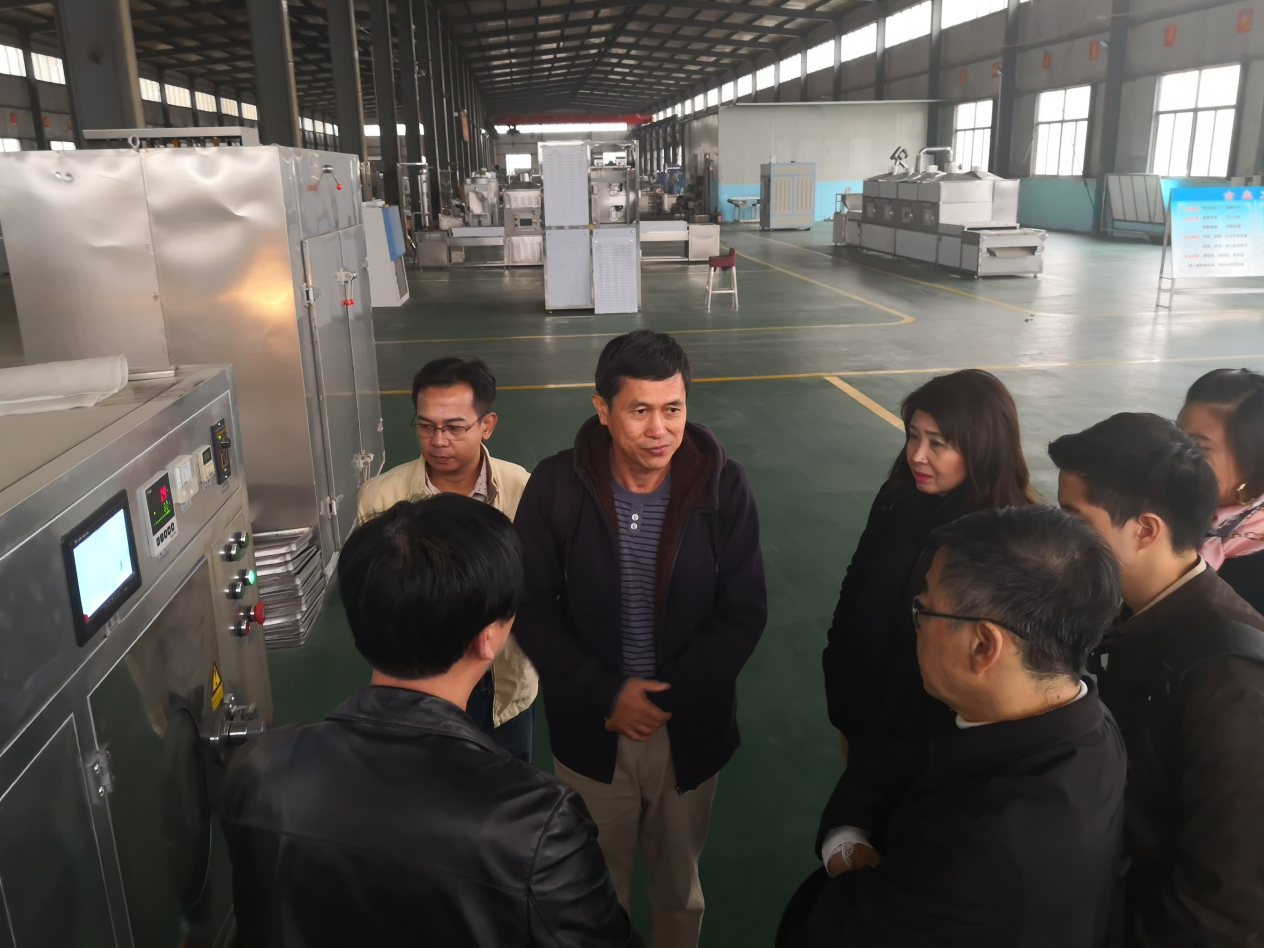

Recently, customers from Singapore contacted us and said that they need to order 20 pet food extruders. There are many distributors on the website. They think we have great advantages. To let them have a more comprehensive understanding of our pet food extruder, we warmly invite them to carry out a field trip and give them a detailed introduction to the advantages of our equipment.

Singapore customer visit

What are the advantages of pet food extruder?

- High production efficiency

The pet food extrusion machine adopts the mechanized production mode, which can work continuously 24 hours after startup. The production efficiency is very high, and there is no extra waste, which helps the manufacturer reduce production costs.

- Fewer production links

Unlike traditional production equipment, pet food extruder can realize integrated production. The produced food can easily go directly to the next production process, without wasting time in the middle, which can greatly improve production efficiency and greatly reduce the staff’s workload.

- Clean and sanitary

The whole machine of pet food extrusion equipment is made of industrial-grade stainless steel, which is very clean and sanitary. The pet food produced is safe and pollution-free, and the whole production environment is also very clean and comfortable so that the staff can work in a cleaner and simpler environment.

4.Low noise

After the traditional production equipment is turned on, the noise will be very loud, which is easy to cause trouble for the staff. The noise of the food extrusion equipment is very low, and the whole production environment is cleaner and more efficient.

5.Good palatability

The food extruder’s pet food can maintain the nutrition of the raw materials to the maximum extent and has good palatability, which can solve the problem of many pets not eating pet food, which is more popular in the market.

Pet food extruder

After careful understanding, Singaporean customers are very aware of our pet food extruder. We recommend several commonly used models to them, hoping that they can find the most suitable one for themselves.

Technical parameters of pet food extruder:

| P

ower |

30KW | 60KW | 90KW | 120KW |

| Yield | 50kg/h | 100/h | 150/h | 200/h |

| Power consumption | 20KW | 40KW | 70KW | 100KW |

| Power voltage | 380V | |||

| Production line length | 18m | |||

| Packaging | General packaging is ordinary packaging, which is packed in ordinary or wooden cases according to different customer regions | |||

| Production cycle | 30-35 days | |||

Pet foods

After our detailed introduction, Singapore customers have a very comprehensive understanding of our pet food extruder and have reached a happy partnership with us. They have ordered 20 pet food extruders from our company. In the future, we will send professional staff to guide the installation, provide them with some special food formulas, etc., to help them gain greater advantages in future production.

Years of development let us gain a lot of loyal customers. They choose the high quality of our equipment. Every customer who cooperates with us has received a surprise, and we will continue to work hard to provide more surprises for our customers!