- Introduce

- Advantage

- Feature

- PDF Download

PDF

PDF

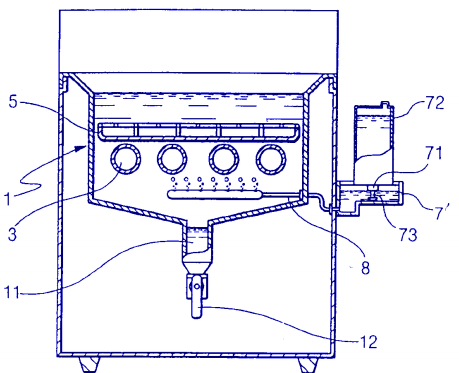

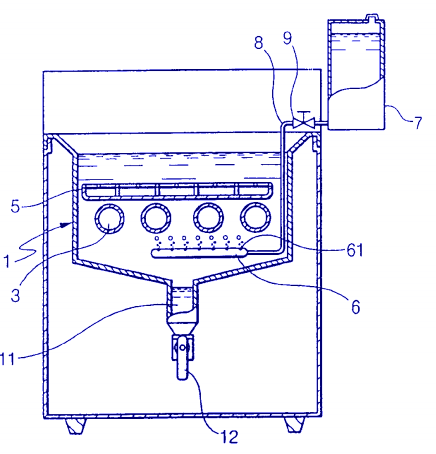

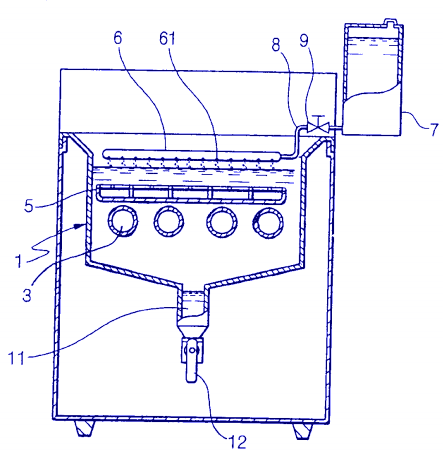

LD1856 Oil-water integrated fryer comprises a frying device and a water supply device arranged separately from the frying device.

In the prior art, when using a fryer to process food, some only use oil to fry food so that the food surface is easily scalded and baked hard, and the oil is easily acidified. For this reason, some add water to the fryer’s oil to make the fried food soft, but the boiling water is easy to explode when frying.

Advantages of LD1856 Oil-water integrated fryer:

Advantages of LD1856 Oil-water integrated fryer:

The fryer adopts the method of setting the frying device and the water supply device separately and uses a porous water spray pipe with small holes to spray evaporated water into the food oil. The oil will not be acidified and discolored even when the fryer’s oil temperature is maintained at 160 ℃ ~ 220 ℃. Water or steam ejected is evaporated out of the atmosphere, and the other part is contained in the oil. The water contained in the oil not only prevents the oil from being acidified but also makes the fried food not dry, soft, and fresh, which is of high use-value.

Configuration of the fryer:

Configuration of the fryer:

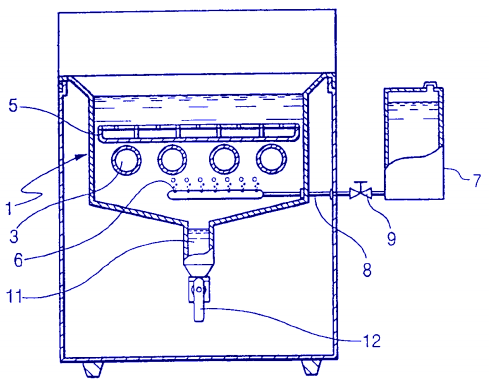

Figure 1

Figure 1

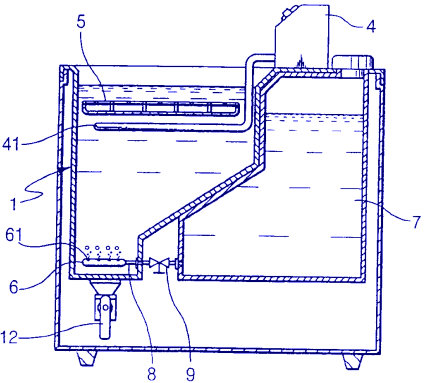

Figure 2

Figure 2

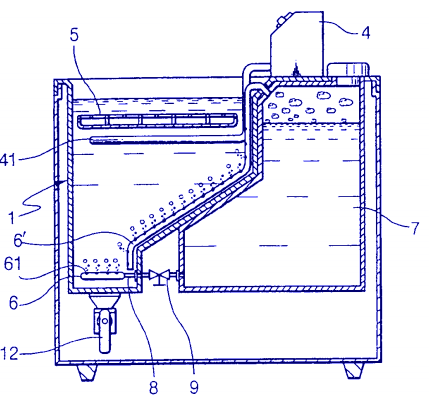

Figure 3

Figure 3

Figure 4

Figure 4

Figure 5

Figure 5

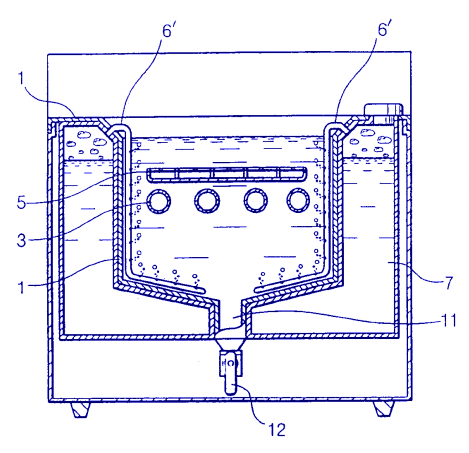

Figure 6

Figure 6

Figure 7

Figure 7

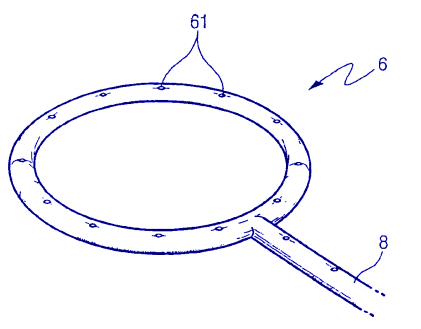

Figure 8a

Figure 8a

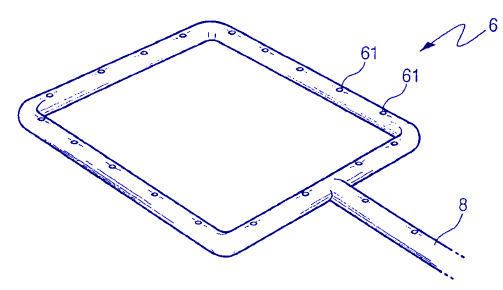

Figure 8b

Figure 8b

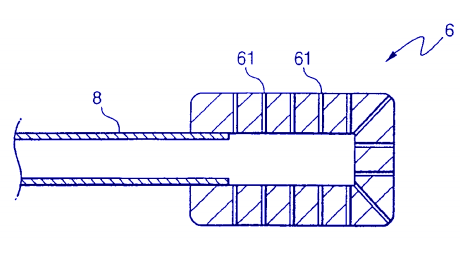

Figure 8c

Figure 8c

Figure 8d

Figure 8d

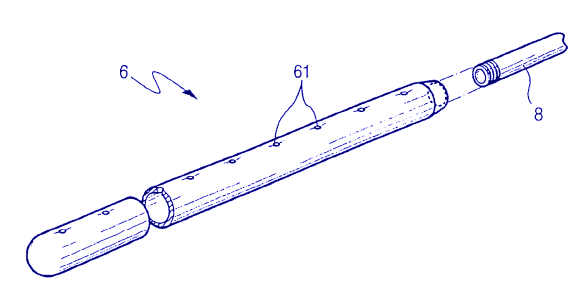

Container 1, heating pipe 3, power supply part 4, fried net 5, porous water spray pipe 6, water tank 7, connecting pipe 8, valve 9, vertical tank 11, valve 12, heating body 41, a small hole 61, porous water spray pipe 6, auxiliary water tank 7 ‘, cover 71, bucket 72, opening 73

Figs. 1-7 are longitudinal sectional views of various different embodiments.

The water supply device in Fig. 1 is arranged outside the fryer.

The water supply device is arranged outside the fryer container and is in contact with the local part.

The water supply device in Fig. 3 is arranged at the position shown in Fig. 2, but the water vapor can be supplied from the upper part of the water supply device.

The water supply device in Fig. 4 is arranged around and in contact with the outside of the fryer container, and can supply water vapor from the upper part of the water supply device.

In Fig. 5, the water supply device is arranged on the outside of the fryer and is in contact with the local part.

The water supply device in Fig. 6 is arranged outside the fryer and separated from it.

The water supply device and the porous water spray pipe in Fig. 7 are arranged in the upper part of the fryer container exposed to the atmosphere.

Figure 8a-8d is the schematic diagram of the porous water spray pipe in the fryer’s water supply device.

Features of LD1856 Oil-water integrated fryer:

Features of LD1856 Oil-water integrated fryer:

1. A heating part consists of several heating pipes that use the heat from the gas pan as the heat source. The heating pipes are arranged from the front to the rear of the container, or the heating body which uses the power supply part on the upper part of the fryer as the heat source is in contact with the power supply part.

2. The water supply device also includes a connecting pipe connected with a porous water spray pipe from the lower side of the water tank. It penetrates from the container’s side into the oil and is connected with the porous water spray pipe, or is connected with the porous water spray pipe from the upper part of the box.

3. The connecting pipe is equipped with a valve to regulate the water supply.

4. The porous water spray pipe is arranged in the oil or in the atmosphere close to the oil surface.

5. The water supply device includes a supplementary water tank for storing and supplying water. The additional water tank is provided with a bucket for supplementing water. The lower part of the bucket is equipped with a cover that can be opened/closed automatically or manually. The porous water spray pipe is perforated with a plurality of small holes to supply water to the oil. The connecting pipe is connected with the porous water spray pipe from the lower side of the supplementary water tank, which is connected with the side of the container Connect with the porous water spray pipe through the oil or connect the porous water spray pipe from the upper part of the box.

6. The porous water spray pipe is made of metal or non-metal materials.

LD1856 Oil-water integrated fryer PDF

LD1856 Oil-water integrated fryer PDF

Advantages of LD1856 Oil-water integrated fryer:

Advantages of LD1856 Oil-water integrated fryer: